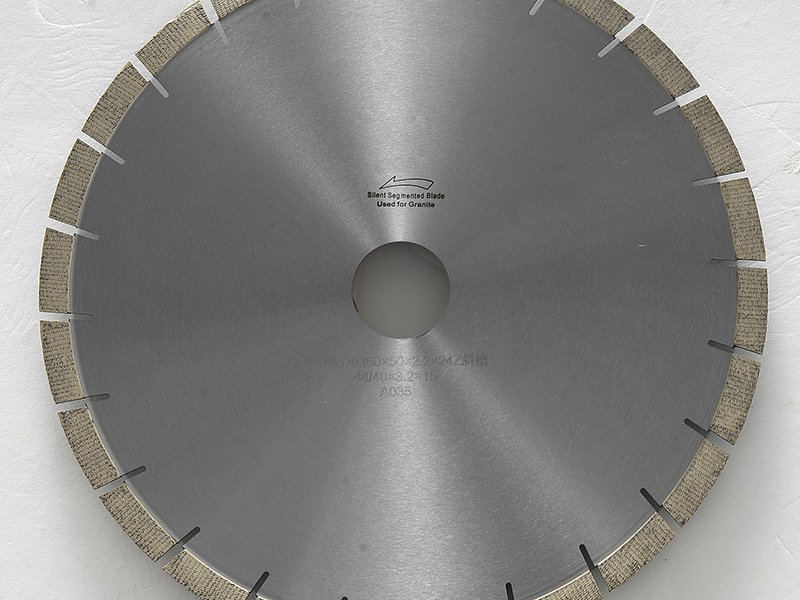

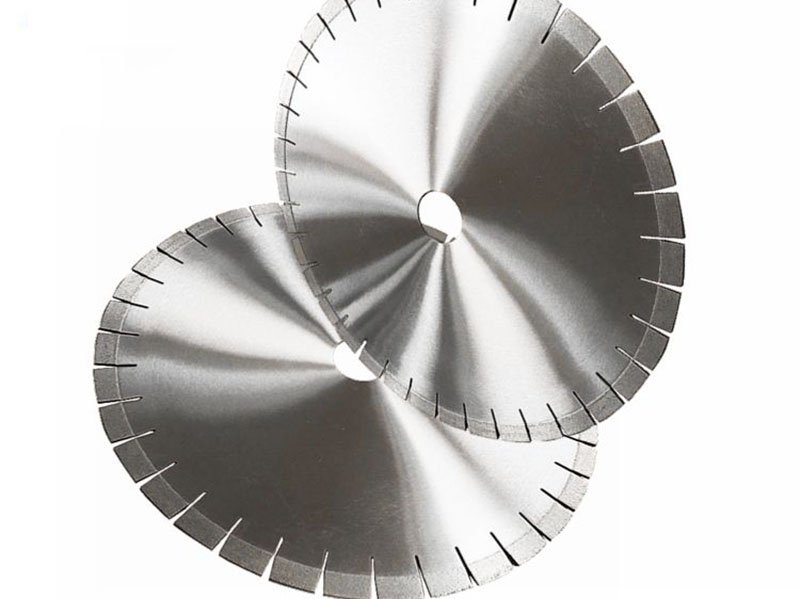

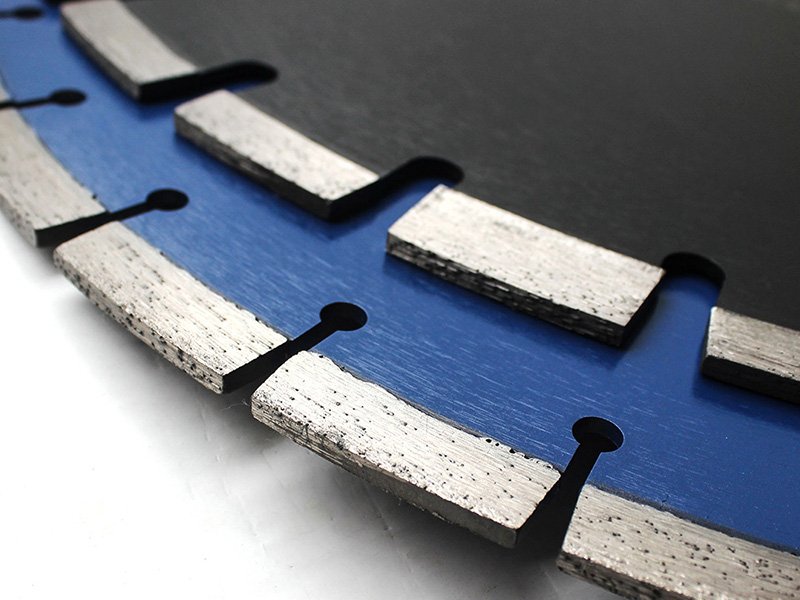

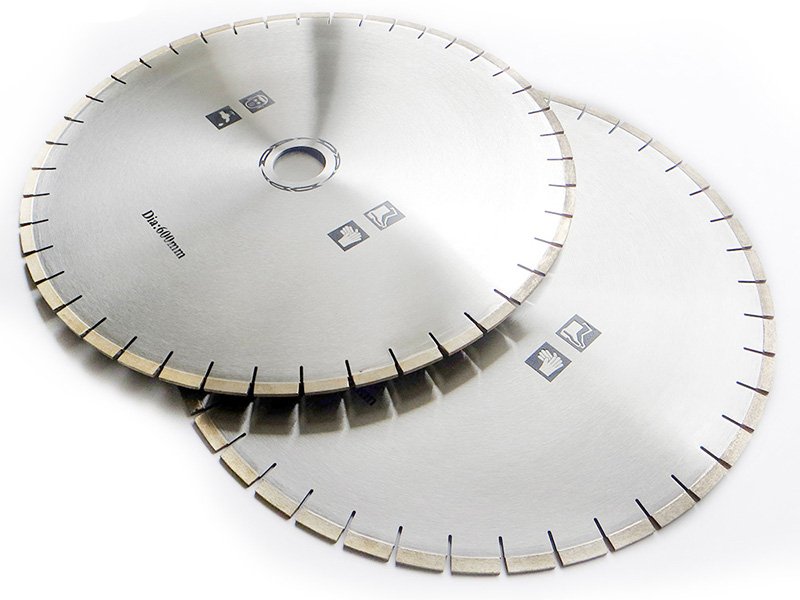

Diamond circular saw blade is one of the earliest diamond tools that has been used, and it is also the most widely used diamond sawing tool at present. The diamond circular saw blade is composed of a base body and teeth(diamond segments), and the teeth are located around the base body. The base body is mostly made of steel, and the segments are sintered from diamond and matrix powder through powder metallurgy process.

In 1885, the Frenchman Jaeguin made serrations with 0.8-carat natural diamonds, which were manually inlaid on the periphery of the base with dovetail grooves, and then fixed with rivets. This is the world’s first diamond-encrusted diamond circular saw blade. After the 1930s, with the gradual maturity of powder metallurgy technology, powder metallurgy technology began to be used in the production of diamond circular saw blades. People mixed and sintered metal powder and diamond into fan-shaped saw teeth, and then welded the saw teeth on the steel substrate by welding, which was the early form of welded diamond circular saw blades.

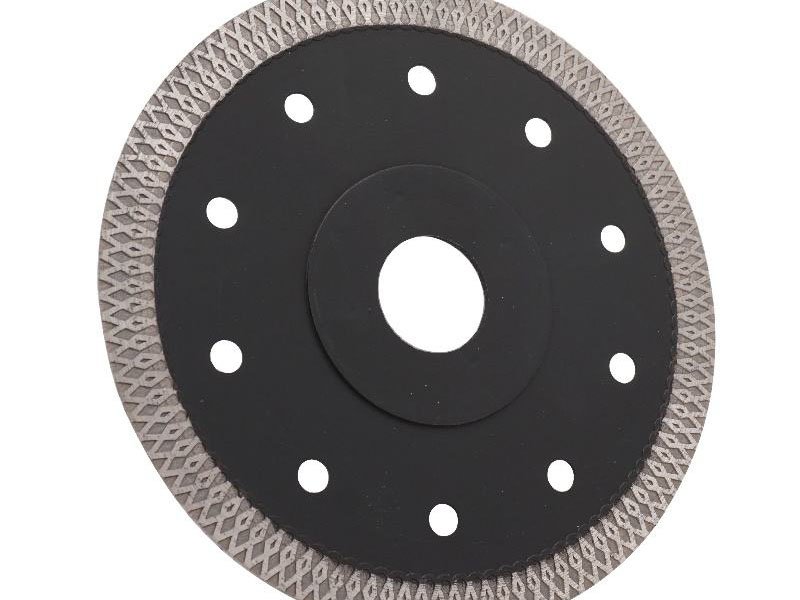

In recent years, with the continuous advancement of manufacturing technology. The processing objects and application fields of diamond circular saw blades are constantly expanding. In addition to the traditional cutting of various hard and brittle non-metallic materials such as stone, glass, semiconductor, etc., it is also widely used in reinforced concrete cutting, airport runway anti-skid joint cutting, highway and square expansion joint cutting, bakelite plate and plastic board cutting. Even in the cutting of wood, aluminum plates, steel cables, and gypsum cement boards, diamond saw blades have been widely used.

Vacuum Brazed Diamond Saw Blades2022-08-23T12:34:08+00:00