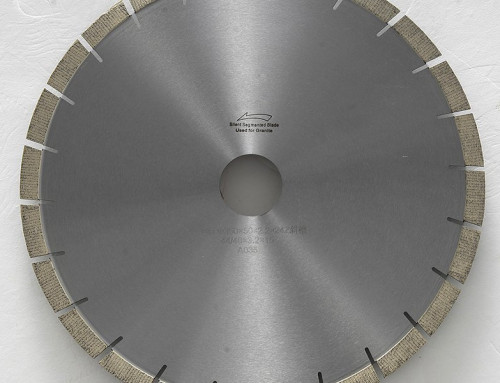

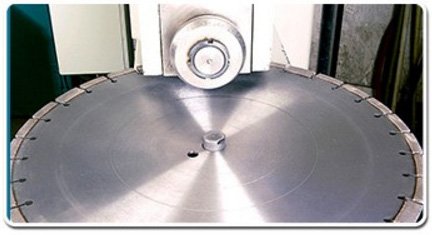

Best Diamond Circular Saw Blades Disc for Cutting Porcelain Tiles Slabs

Best Diamond Circular Saw Blades Disc for Cutting Porcelain Tiles Slabs can be supplied by Eonyx, which is the leading manufacturer of diamond saw blades. Our sophisticated factory can supply 20,000 pieces of saw blades per month. As a professional supplier, we can guarantee competitive wholesale price and stable quality.

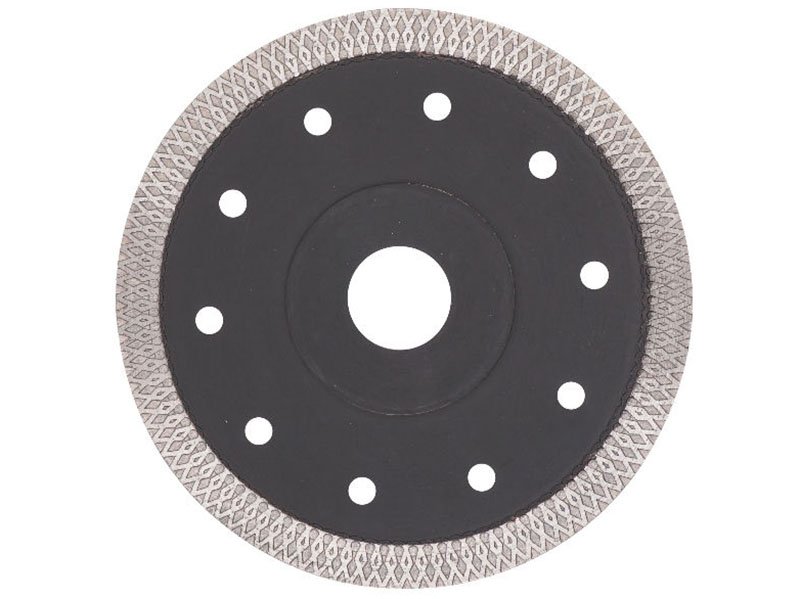

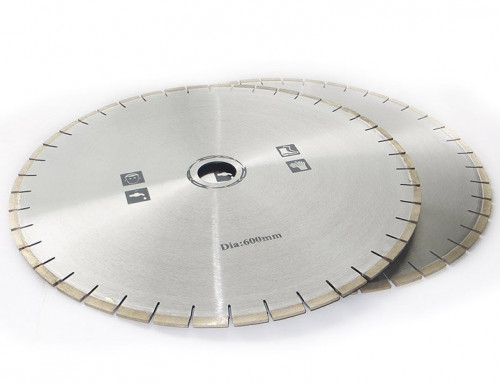

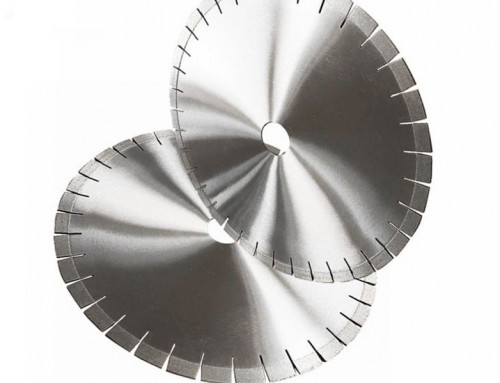

Sizes of Diamond Circular Saw Blades Disc for Cutting Porcelain Tiles Slabs

The regular diameters of diamond saw blades range from 100mm to 3500mm. Among them, the popular sizes are: 2 inch, 3 inch, 3 3/8 inch, 4 inch, 4 3/8 inch, 4 1/2 inch, 5 inch, 5 3/8 inch, 5 1/2 inch, 6 inch, 6 1/2 inch, 7 inch, 7 1/4 inch, 7 1/2 inch, 8 inch, 8 1/4 inch, 9 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, 26 inch, 30 inch, 36 inch, etc. (110mm, 160mm, 165mm, 255mm, 300mm, 350mm, 400mm, 3m, etc.)

Saw Blades Processing Process

We have been focusing on the technical development and production of diamond tools for more than 28 years.

1. Powder Milling

2. Segment Pressing

3. Segment Sintering

4. Segment Welding

5. Welding Strength Inspection

6. Stress Release Rolling

7. Blade Polishing

8. Blade Painting

Quality Inspection

Excellent product quality is our commitment to customers as always.

Processing technology and quality control points of diamond saw blades for cutting porcelain tiles

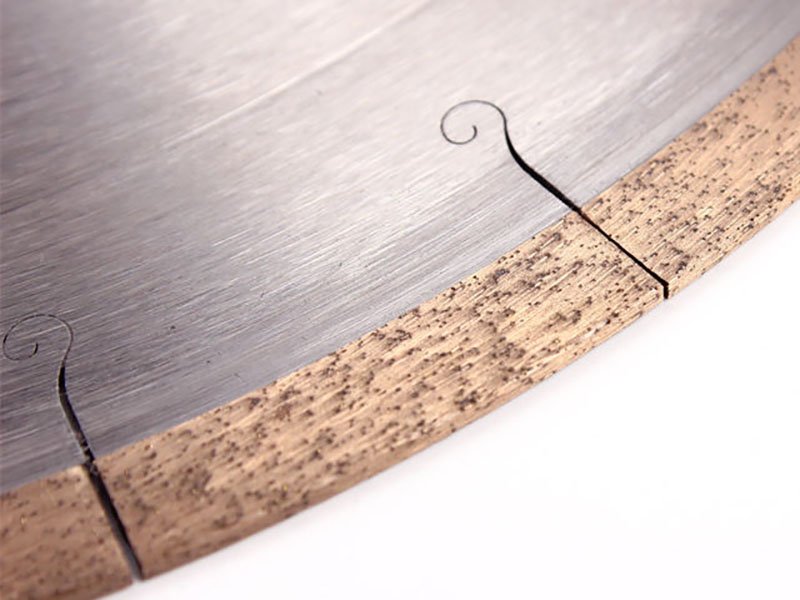

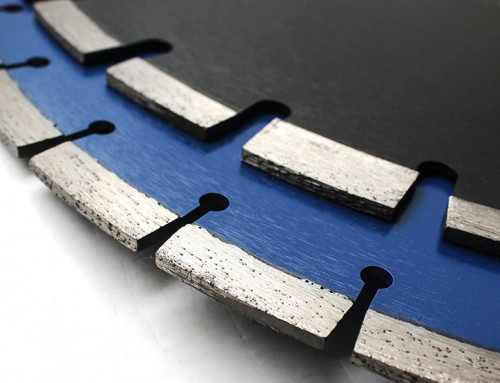

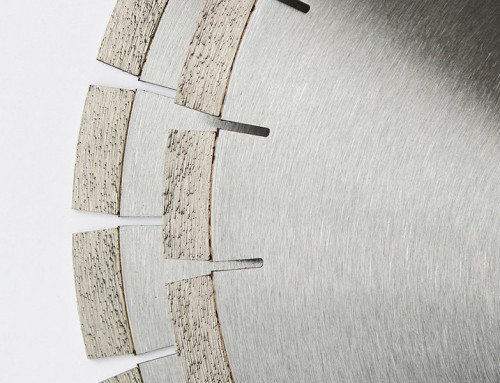

After the hot pressing of the diamond segments of the diamond saw blade is completed, it needs to be ball milled to remove burrs, and the welding surface will be polished before it can be transferred to the welding process. In order to ensure the quality of subsequent processing such as welding and cutting, the appearance and size inspection of the finished diamond bit should be carried out. The diamond saw blade for cutting porcelain tiles mainly has the following defects, which have adverse effects on the subsequent processing of finished products: (1) The cutting surface of the diamond saw blade has large and small diamond segmentss on both ends of the pressing surface. If the maximum length of the edge and defect exceeds 3mm, it will affect the appearance of the product, and it is also easy to cause fine knife marks; (3) The maximum length of the protrusion of the knife diamond segments caused by the edge drop of the mold or the defect of the pressing surface is greater than 2mm, and the thickness is greater than 0.3mm, the Difficulties in cutting the diamond saw blade, if it is on the inner side of the edging wheel diamond segments, it is easy to cause chipping corners: (4) The pit defects of the welding surface caused by the inclusion of graphite are larger than 10% of the total area, And the maximum depth is greater than 0.3mm, which will cause insufficient welding strength. The diamond segments with the above defects must be removed for rework and not flow into the finished process.

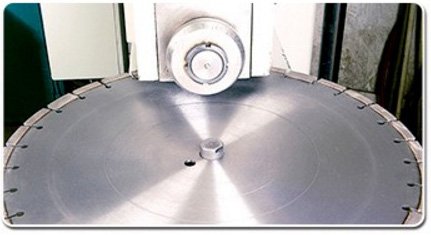

The finished product processing of the diamond saw blade for cutting porcelain tiles is to weld the diamond segments to the base, trim the cutting edge, process the base mounting inner hole and fixing screw hole in place according to the accuracy requirements, and implement dynamic balance detection. The whole sintered product does not need welding process, and other processes are the same.

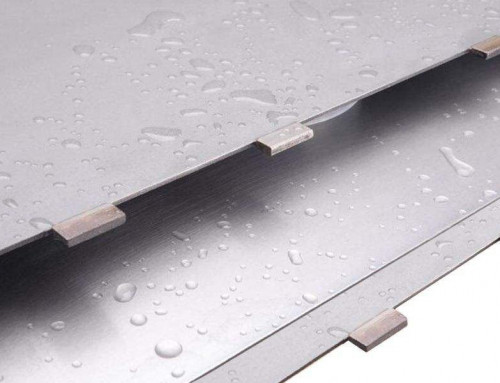

Substrate machining of diamond circular saw blades for cutting porcelain tiles

The base material of diamond saw blade is generally gas-cut or forged with 2~8mm thick A3 steel plate, the base of hob is generally 219mmx14mm A3 or No. 15 cold-rolled seamless steel pipe, and other products are basically forged A3 or No. 35 blank. Generally speaking, welded diamond circular saw blades and hob bases can be used many times after being refurbished. At present, all tool manufacturers basically use recycled bases many times to save costs. Recycling the matrix should be based on the premise of not affecting the quality of use, otherwise it will not be worth the loss. In order to improve the recycling times of the substrate, it should first be processed according to the inner hole and the fixed screw hole position; then the inner hole should be enlarged or the outer diameter should be reduced. Under normal circumstances, the thickness of the base of the diamond saw blade is less than 6mm, the wall thickness of the base cylinder of the hob is less than 8mm, and in the case of serious deformation, it should be scrapped and should not be used for recycling. When recycling the hob base, pay attention to when the distance between the two ends of the flange is shorter than the new base by more than 5mm, and it is necessary to add gaskets or reposition the cutting line, otherwise it will easily cause the scraping surface of the installed hob to shift. The matrix of the diamond saw blade used for cutting porcelain tiles should be dynamically balanced before the welding diamond segments. If the dynamic balance exceeds 80g, it should be aggravated first, otherwise the deformation will be larger and the imbalance will be more serious after welding. The hob base body can reduce the resonance noise of the cylinder during use by adding an inner tube and a central flange to the cylinder.

Welding of saw blades for cutting porcelain tiles

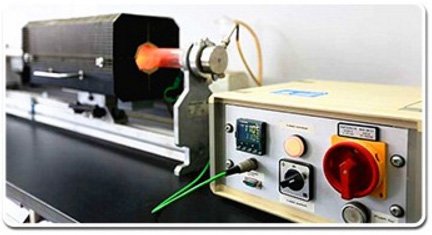

The welding of the saw blade for cutting porcelain tiles is carried out on a high-frequency welding machine. In order to ensure the welding efficiency, the power of the welding machine is required to be 30~40kW. Welding diamond saw blades use a special welding frame with two-way movement and rotatable installation shaft, and a rotary welding table is required for welding edge grinding wheels. According to the size and shape of the weldment, induction coils of different shapes and sizes should be equipped and used. The edging wheel and chamfering wheel should use ф300, ф250, ф200, ф150 heating induction coil, and the hob, counter-grinding wheel and cylindrical wheel should be heated at the same time 2 ~ Long frame induction coil with 3 diamond segmentss. According to the different formulations of diamond tips, use silver pads with a silver content of 15% to 30%. The higher the silver content, the lower the melting point. Therefore, the higher the sintering temperature of the tip, the lower the silver content of the available silver pads. When soldering, the silver solder piece must be used with flux. The brazing flux can promote the reduction of oxides on the surface of the solder, promote the melting of the silver solder piece, and improve the fluidity of the solder piece.

Before welding, the base welding part of the saw blade should be ground with a grinder to remove oxide skin and burrs, and the welding part of the blade diamond segments should be cleaned with alcohol or tena water. Choose the appropriate size of solder tab and clean it with clean water. The silver brazing flux powder is added to the appropriate amount of water and boiled into a thin paste. Brush a layer of flux on the welding part of the base body, and then place the solder dipped in the flux on the welding part with tweezers, and put the cleaned diamond bit on the welding part. On the solder pad, start the switch to start heating. During the heating process, pay attention to rotating the base of the saw blade to keep the heating even. The spacing between them should be even. During the welding process, the welding current of the high-frequency welding machine is 25~60A, and the maximum welding power is 25kW. The welding temperature is the temperature at which the melting begins by visual observation. Pay attention to control the welding temperature during welding. When welding a saw blade for cutting porcelain tiles, as the welding blade melts. Keep pressing the diamond segments with tweezers. When welding the hob, use tweezers to clamp the diamond segments close to the side of the spiral mark on the surface of the cutter body and gently move the diamond segments, so that the diamond segments is fully combined with the base of the saw blade. Add a small amount of flux on both sides of the diamond segments to increase the strength of the weld. After the welding is completed, cut off the power supply, hold it firmly and remove the workpiece, put it aside and let it cool down naturally before transferring to the next process.

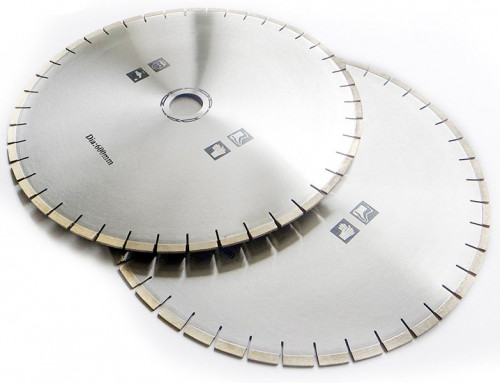

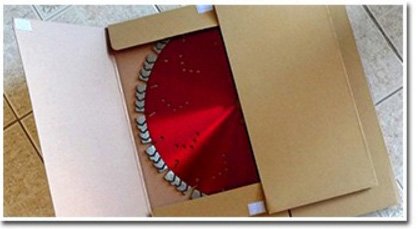

Inventory and Packaging

Sufficient inventory to ensure delivery and professional packaging to ensure safe transportation. Inner packaging: diamond saw blades are covered by anti-rust paint and plastic, then packed in paper box. Outer packaging is according to the shipping method, if by air, we recommend carton which could reduce weight; if by sea, we recommend crate which is seaworthy. Other packaging is also available upon your request.

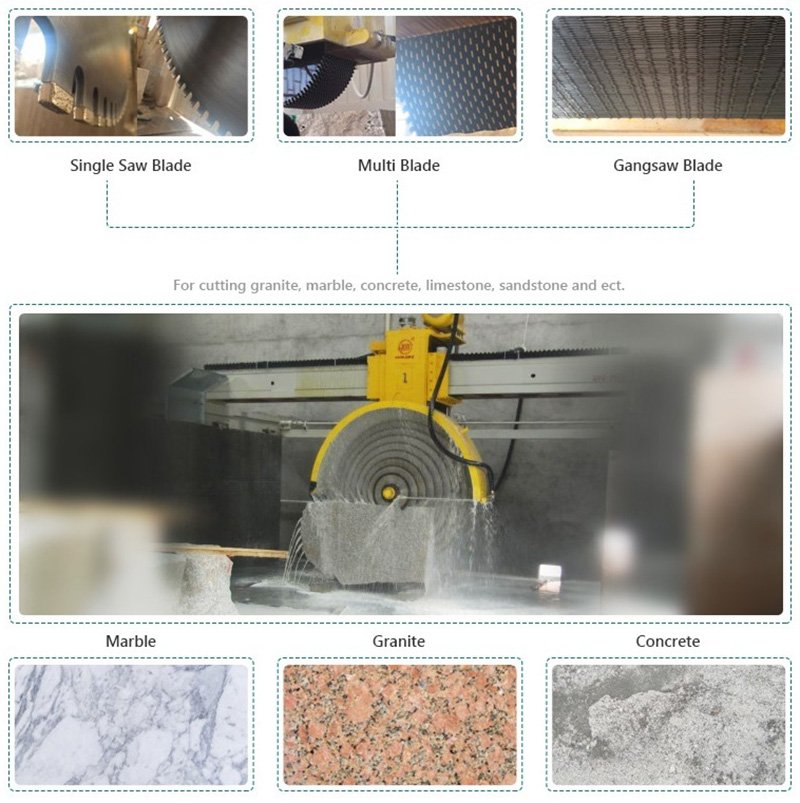

Application of Diamond Cutting Blades

For multi blade cutter, gang saw blade, bridge cutting machine, single arm cutting machine, manual handing machine, able cutting machine, etc. Designed for various hardness stone (soft, medium hard and very hard stones) cutting: granite, marble, sandstone, onyx, limestone, travertine, quartz stone, artificial stone, andesite, volcanic, lava stone, basalt, microcrystal stone, blue stone, dolomite and construction materials (concrete, tile, ceramic, asphalt, floor) to reduce segment cost and increase cutting efficiency.

Edge of circular saw blade for cutting porcelain tiles

The purpose of the cutting edge of the circular saw blade is to expose the diamond on the surface of the tool, remove the grinding surface and side burrs or protrusions, improve the concentricity of the outer circle of the diamond saw blade, and increase the aesthetic effect. The circular saw blades and chamfering wheels for cutting porcelain tiles are carried out on a special edger, and the hob, cylindrical wheel and counter-grinding wheel are carried out on a universal cylindrical grinder. It is installed with various specifications of open-edged mandrels, and used for grinding with brown corundum and white corundum grinding wheels. Grinding wheels and chamfering wheels require a 100% edge opening rate of the grinding surface, a side edge opening rate of more than 90%, and an end face chamfering of 2mmx45°. For the edge grinding wheel, first rough edge and side grinding are carried out on a special edger for edge grinding wheel, and the fine edge is sharpened. After turning, perform fine cutting on the universal cylindrical grinder, and the cutting rate of fine cutting is not less than 98%. The cutting edge of the hob is carried out on a universal cylindrical grinder, and it is required that the cutting edge rate of the diamond segments should not be less than 98%. Cylindrical wheel edging is carried out on a universal cylindrical grinding machine. Since the cylindrical wheel has high requirements for concentricity accuracy, rough turning and rough cutting should be performed first; then fine turning and fine cutting. Before cutting edge, the workpiece is ground through the end face, and then a set of special shafts are installed together in the same direction, tightened with locking nuts, and the distance between the two tops of the bed surface is adjusted to match the size of the core shaft of the cutting edge. The rate of rough edge is not less than 90%, and the rate of fine edge is 100%.

Finishing and drilling of saw blades for cutting porcelain tiles

Due to the deformation of the substrate during the welding process, the size or shape tolerance of the mounting hole will change. In order to ensure its accuracy, diamond circular saw blades for cutting porcelain tiles require fine turning, except for the hob with flange. If a grinding surface is used as a clamping surface, the edge must be finished first and then finely turned. Cylindrical wheels and counter-grinding wheels that require high concentricity of the grinding surface need to be roughed first, and then finely turned after fine turning. Drilling and tapping can only be carried out after finishing turning. Drilling is carried out on a cross table vertical drilling machine, and a small ordinary drilling machine is used for tapping. After drilling, use a slightly larger drill to chamfer the product on both sides. The chamfers are required to be flat and of the same size. When tapping, it is required to use the corresponding tap and align it, otherwise it is difficult to meet the requirements of concentricity. After tapping, it is required to check whether the screw can be screwed in and in place.

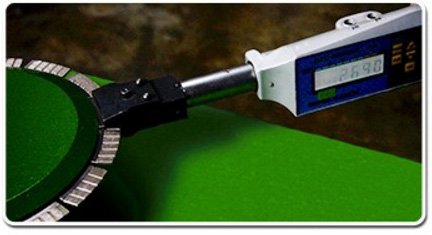

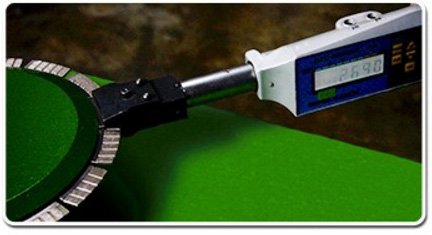

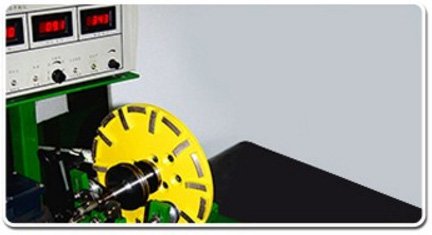

Dynamic balancing of porcelain tiles slabs cutting blades

Dynamic balance is a very critical process, which is related to whether the workpiece is stable and vibrated when it is used. The general speed of porcelain tile cutting saw blades is above 1400r/min, and the unbalanced state has a fatal impact on the use process and processing quality. Dynamic balancing equipment generally adopts intelligent dynamic balancing instrument, its core is a microcomputer, and there is special software for dynamic balance measurement. All kinds of supporting mandrels used must be tested by dynamic balance first, and should be tightly fitted with the center hole, and a little external force should be applied to tap the mandrel into the center hole. Note that the tightness should be moderate, too tight will strain the inner hole of the hob; too loose, the balance result will be inaccurate. Place the workpiece with the mandrel on the bracket of the balancer and fasten it. Place a small magnet on the right end of the balance shaft so that it faces the sensor and maintains a proper distance from the sensor. Dynamic balancing operation procedure, when the rotation speed reaches the specified requirement (about 800r/min), the screen will display the weight that should be removed from the left and right ends and the degree it is in, and the edging wheel can record and remove one side.

The unbalanced weight of the diamond circular saw blade used for cutting porcelain tiles should be less than 2g, the unbalanced weight of the hob with a base length of 690mm (including 690mm) or more should not exceed 30g; the unbalanced weight of the hob below 690mm should not exceed 20ge If the unbalanced weight exceeds the standard, the method of drilling and deweighting or weighting should be adopted to balance the product. The edging wheel, the grinding wheel and the cylindrical wheel are drilled and deweighted. When the unbalance of the hob is small (generally less than 50g), use the drilling method to remove weight, and when it is large, use the weighting method, and use b14mm round steel to weld to the corresponding position to balance the product.

Contact Us

If you’re interested in Best Diamond Circular Saw Blades Disc for Cutting Porcelain Tiles Slabs, please feel free to contact us, (E-mail: [email protected] Phone/WhatsApp: 0086-15805032000 or filling out the form below) we will keep providing quality products and excellent service for you.