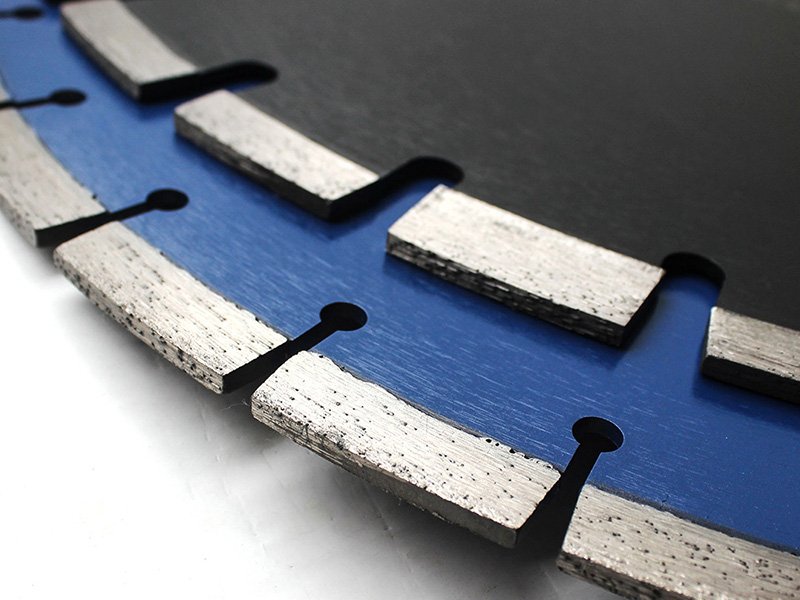

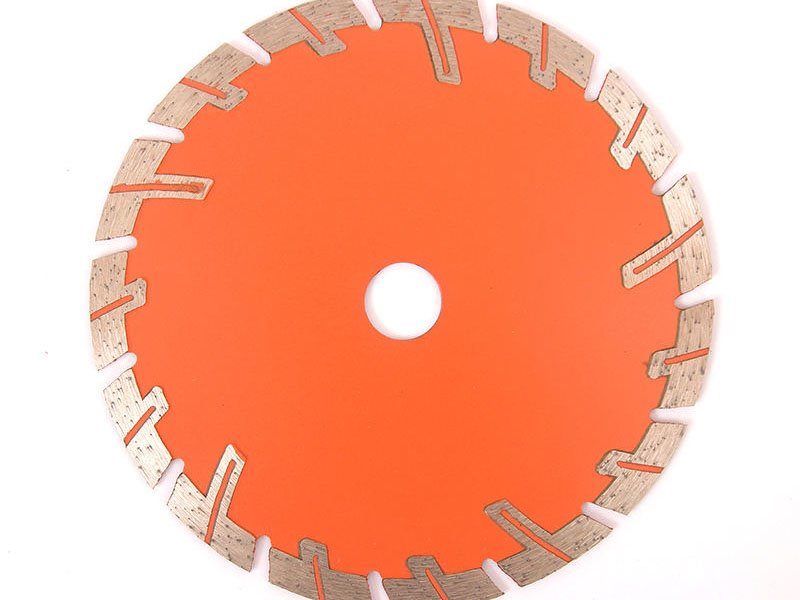

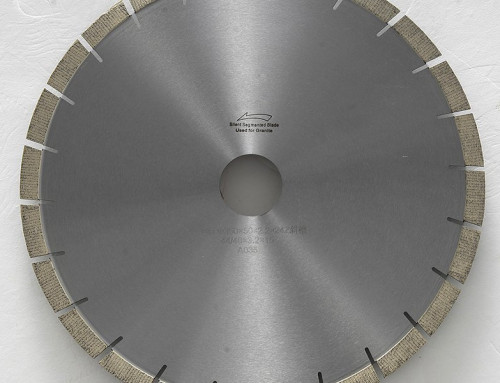

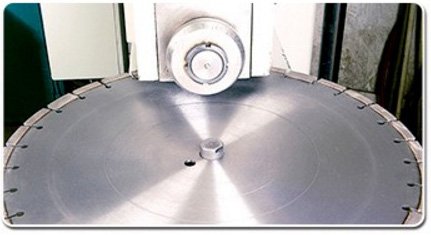

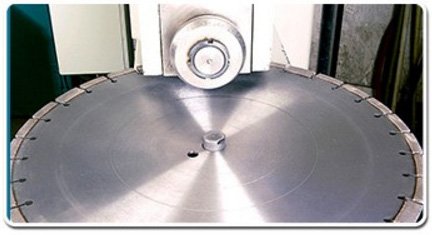

Best Concrete Cutting Diamond Circular Saw Blades Disc for Block Slab Pavers Suppliers Price for Sale

Eonyx is the leading manufacturer of Best Concrete Cutting Diamond Circular Saw Blades Disc for Block Slab Pavers. Our sophisticated factory can supply 20,000 pieces of saw blades per month. As a professional supplier, we can guarantee competitive wholesale price and stable quality.

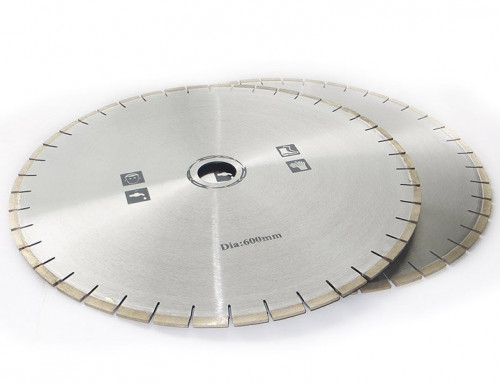

Sizes of Concrete Cutting Diamond Circular Saw Blades

The regular diameters of diamond saw blades range from 100mm to 3500mm. Among them, the popular sizes are: 2 inch, 3 inch, 3 3/8 inch, 4 inch, 4 3/8 inch, 4 1/2 inch, 5 inch, 5 3/8 inch, 5 1/2 inch, 6 inch, 6 1/2 inch, 7 inch, 7 1/4 inch, 7 1/2 inch, 8 inch, 8 1/4 inch, 9 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, 26 inch, 30 inch, 36 inch, etc. (110mm, 160mm, 165mm, 255mm, 300mm, 350mm, 400mm, 3m, etc.)

Saw Blades Processing Process

We have been focusing on the technical development and production of diamond tools for more than 28 years.

1. Powder Milling

2. Segment Pressing

3. Segment Sintering

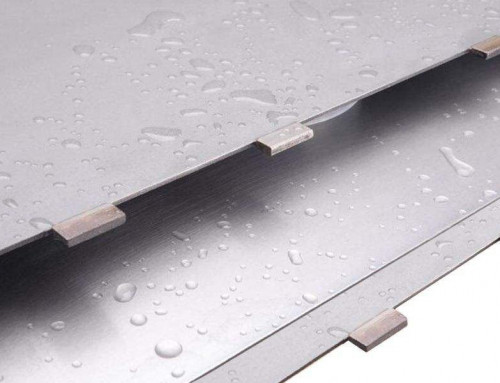

4. Segment Welding

5. Welding Strength Inspection

6. Stress Release Rolling

7. Blade Polishing

8. Blade Painting

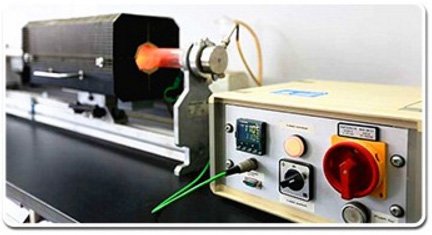

Quality Inspection

Excellent product quality is our commitment to customers as always.

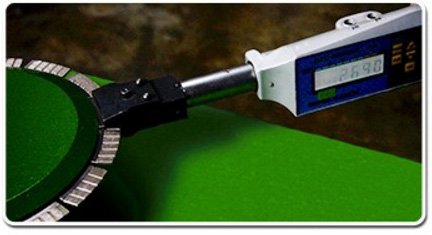

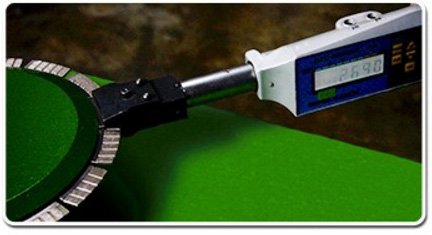

Inspection of diamond circular saw blades for cutting concrete

The inspection items of diamond circular saw blades for cutting concrete include appearance, geometric dimensions, saw blade end runout and radial runout, substrate hardness and flatness, and diamond tip strength.

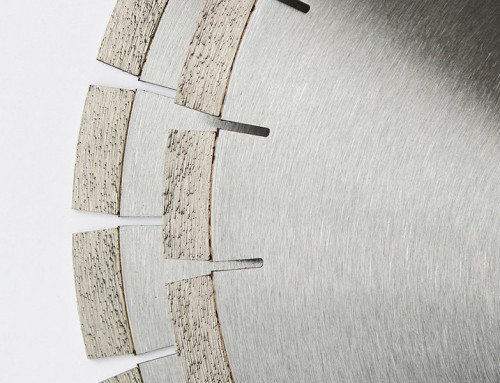

Appearance of saw blades for cutting concrete

The appearance quality of the diamond circular saw blade should be inspected visually or with a 10x magnifying glass, and the chipping should be inspected with a sample plate or a vernier caliper with an index value of 0.02mm.

Appearance requires that there should be no cracks on the surface of each tooth and no more than 2 chipping edges with a length and width of 1mm, and the sintered piece should not have a mute sound. The saw blade with an outer diameter of less than 600mm needs to be edged, and the diamond particles on the working surface should be exposed and evenly distributed. If the substrate is painted, the coating should be uniform, smooth, free of spots and scratches. The welding saw blade requires that the weld be full, there should be no cracks and holes, and the solder accumulation should not be higher than the end face of the sawtooth.

Circular saw blade geometry

The external dimension of the diamond circular saw blade for cutting concrete is detected with a vernier caliper with a division of 0.02mm, and the diameter of the saw blade is detected with a smooth hole plug gauge or an inner diameter micrometer. The base body of the saw blade and the external dimensions of the saw teeth are tested with a steel tape measure, a steel ruler and a vernier caliper, and the inner hole diameter is detected with a vernier caliper or an inner micrometer with a special plug gauge indexing value of 0.02mm. The end-face symmetry detection of the cutter teeth on the base body is detected with a special tool with a dial indicator.

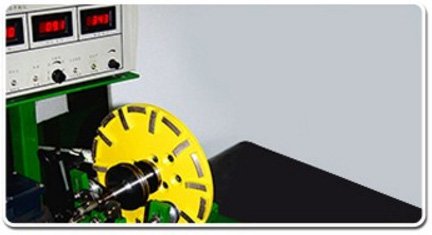

Blade face and radial runout

The testing instrument required for the end face and radial runout of the diamond circular saw blade is a circular runout instrument. The radial runout of the mandrel shall not be greater than 0.01mm, and the runout tolerance of the flange end face shall not be greater than 1/10 of the end face runout tolerance value of the measured saw blade. The diameter of the flange shall not be greater than 1/3 of the diameter of the saw blade being tested. The diameter of the flange of the saw blade with an outer diameter of less than 400mm shall not exceed 1/2 of the diameter of the saw blade under test.

When detecting the end face of the saw blade and the radial runout, use the flange to fix the saw blade on the mandrel, place the dial indicator contacts on the outer diameter of the saw blade and the side of the base at 10mm from the bottom of the groove, rotate the saw blade slowly, and read The value on the dial indicator is the radial and end face circular runout value of the saw blade.

The hardness and flatness of the matrix of the diamond saw blade

The hardness of the substrate is tested with a Rockwell hardness tester. According to the different materials and processes, the hardness of the general welding saw blade substrate ranges from 33 to 45HRC. When testing, check any three points, and the hardness value is required to be between ±2 of the average value. The flatness of the substrate is checked with a 500:002 flat ruler and feeler gauge. The flatness of the saw blade with an outer diameter of less than 400mm is tested with a 50~300mm knife edge ruler and a feeler gauge.

Testing of bond strength of diamond circular saw blade for cutting concrete

The bonding strength of the diamond circular saw blade largely determines the use effect of the product. In the process of saw blade cutting concrete, due to the insufficient bonding strength between the saw blade and the substrate, the individual saw teeth are broken and thrown out, which will seriously threaten the safety of the operator and also affect the service life of the saw blade. Therefore, the detection and control of the bonding strength of diamond saw blades is very important.

Regarding the detection of the bonding strength of diamond circular saw blades, it is mentioned in GB/T112701-2002 and GB/T11270.2-2002. It is recommended to use the ZMC-A type diamond saw blade saw tooth bonding strength tester for testing in the standard, but for For manufacturing enterprises, the practicability of this testing instrument is poor. Generally, the main tool for testing the bonding strength of welding saw blades is a torque wrench, or testing equipment is used for testing, such as the domestic AWB4 automatic bonding strength testing machine and the German SPE bonding strength testing machine. Ultrasonic measurement method is a new type of measurement method for the welding quality of laser welding saw blades. . The main advantage of this measurement method is the non-destructive nature of the measurement.

The detection index of the bonding strength is generally expressed by the bending moment M, and can also be expressed by the bending strength. The former is mainly used in the actual production testing process, and the latter is mainly used in product development and design. And many large export-oriented enterprises, mainly based on EN13236:2001E “Superabrasive Abrasives Safety Requirements” to formulate the internal control guidelines of the enterprise. According to the EN standard, saw blade bonding strength testing is divided into destructive testing and non-destructive testing.

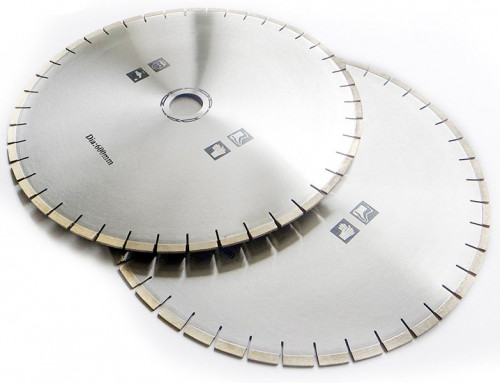

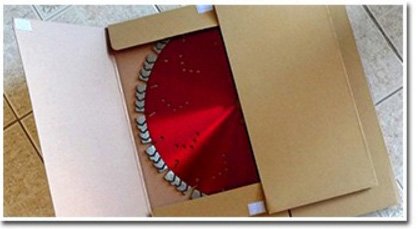

Inventory and Packaging

Sufficient inventory to ensure delivery and professional packaging to ensure safe transportation. Inner packaging: diamond saw blades are covered by anti-rust paint and plastic, then packed in paper box. Outer packaging is according to the shipping method, if by air, we recommend carton which could reduce weight; if by sea, we recommend crate which is seaworthy. Other packaging is also available upon your request.

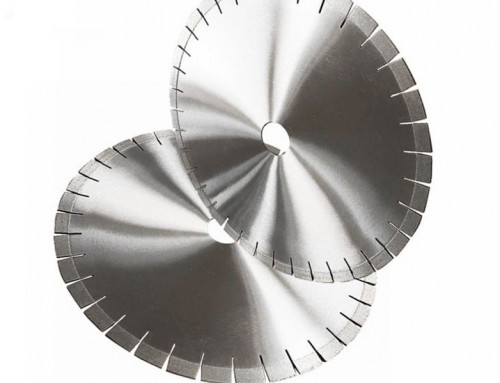

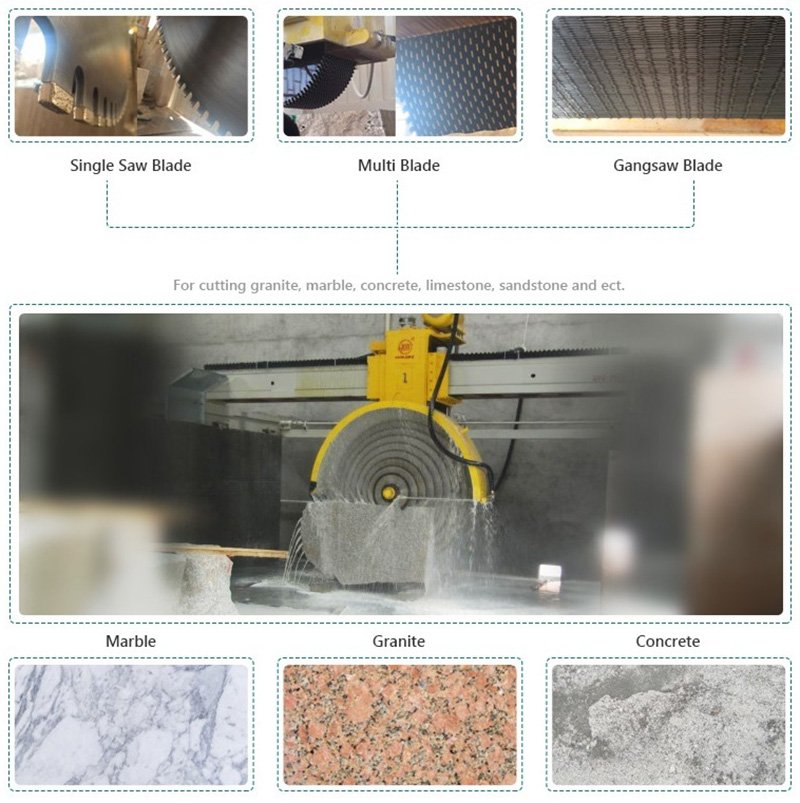

Application of Diamond Cutting Blades

For multi blade cutter, gang saw blade, bridge cutting machine, single arm cutting machine, manual handing machine, able cutting machine, etc. Designed for various hardness stone (soft, medium hard and very hard stones) cutting: granite, marble, sandstone, onyx, limestone, travertine, quartz stone, artificial stone, andesite, volcanic, lava stone, basalt, microcrystal stone, blue stone, dolomite and construction materials (concrete, tile, ceramic, asphalt, floor) to reduce segment cost and increase cutting efficiency.

Performance evaluation of diamond circular saw blade in concrete cutting (cutting performance test and diamond wear morphology analysis)

At present, the performance test of the diamond circular saw blade for cutting concrete is generally carried out based on the use report provided by the user. This method is the most accurate, but the test cycle is long, the cutting is the largest, and the cost is high. In recent years, many fast and convenient experimental methods and experimental devices have appeared in many areas, such as the single-piece cutter head test method. In this method, only one cutter head is used to saw concrete, and the performance of the matrix material and saw blade is evaluated according to the efficiency, quality, wear and edge of the diamond.

Judging the cutting effect of diamond circular saw blades is mainly based on three indicators, namely sawing efficiency, service life and processing quality. Sawing efficiency is an indicator of productivity, usually expressed in cm/min or m/h. It is a sign of the sharpness of the saw blade and an important indicator that users pay attention to first. Service life is an indicator of dry working ability, or an indicator of durability. It refers to the total number of concrete slabs that a pair of saw blades can process, expressed in area, and sometimes measured in meters. The service life is related to the processing cost and is an indicator that users and manufacturers pay attention to.

The processing quality is the quality of the concrete board cut by the saw blade, mainly referring to the surface flatness, straightness, parallelism of both sides, and edge integrity. When the diamond saw blade is sawing concrete, the diamond will appear in different wear states, and the ratios generated by these states also directly affect the cutting performance of the saw blade. In the process of dry sawing, the wear patterns of diamonds have been classified differently by different researchers. But in general, it can be divided into five types: initial shape (complete shape), polished shape (polished shape), partial broken shape, large area or overall broken shape, and shedding shape.

Contact Us

If you’re interested in Best Concrete Cutting Diamond Circular Saw Blades Disc for Block Slab Pavers Price, please feel free to contact us, (E-mail: [email protected] Phone/WhatsApp: 0086-15805032000 or filling out the form below) we will keep providing quality products and excellent service for you.