Professional Manufacturer for Diamond Wire Saw Cutting Concrete

When cutting reinforced concrete components, diamond wire saws require high strength and cutting performance, so the beads of diamond wire saws are generally sintered beads and fixed by spring and rubber. For the applications of cutting reinforce concrete, diameter 10.5/11.5mm rubber and spring diamond wire saw is recommended. The wire saw is widely used in the reinforced concrete with more than 5% steel inside. It is used in the building constructions, cutting for houses, bridges, cement pipes and under water buildings, etc.

Best Diamond Wire Saw for Cutting Concrete is for sale at competitive price here at Eonyx, and as a professional diamond tool manufacturer, we can guarantee the production capacity of 60,000 meters of diamond wire saw every month. Our factory can supply various types and sizes of diamond wire saw to meet the different needs of customers.

Application of concrete diamond wire saw in construction field

Diamond wire saws are continuously used in the construction industry, including the demolition of old buildings, the division of bridges and large concrete facilities. Due to the rapid development of the construction industry in our country, especially the amount of urban demolition and reconstruction is huge. The application market of wire saw in this field is very broad. The wire saw used in the construction field is generally brazed and injection-molded, and in many cases, dry-cutting is used. Its huge market potential is worthy of the efforts of the industry. Building materials are very important to almost every part of people’s lives. Depending on the specific use of the house construction, a large number of materials of different properties are used. As these buildings require constant remodeling and renovations, these materials need to be cut and remodeled with linear cutting tools. Wire sawing systems are widely used in sawing metal, stone and concrete.

Other applications for diamond wire saws

Diamond wire saw cutting and salvaging sunken ships

On December 14, 2002, the Tricolor cargo ship was en route from Zeebrugge to Southampton when it collided with a German container ship bound for Kariba port due to dense fog and sank. By using the diamond wire saw technology to saw the sunken ship into small pieces weighing 3,000t, and then transporting them to the port of Zeebrugge for processing one by one, this is obviously a great improvement in the use of diamond wire saws to salvage the sunken ship.

Cutting of underwater oil pipelines

The underwater oil pipeline is a composite material composed of a concrete outer layer, a polyethylene anti-corrosion layer, a polyurethane thermal delay and a steel pipe layer. When repairing submarine oil pipelines, it is often necessary to cut off the damaged parts, which is a difficult task to complete underwater. The diamond wire saw can independently and effectively complete the task of cutting oil pipelines. The smelting furnace renovation project of large iron and steel enterprises also uses a large number of diamond wire saws, which have the advantages of small slits, simple operation, environmental protection, and strong component cutting ability, which can save a lot of renovation costs for enterprises.

Dismantling oil and gas rigs

When ocean resources are exhausted, oil and gas drilling platforms are abandoned and dismantled, and diamond wire saws are playing an important role. Oil companies have successfully tested a North Sea drilling rig with diamond wire saws. The wire saw is up to 100m long, driven by a hydraulic motor, and the processing speed can reach 25m per second.

Basic structure of concrete diamond wire saw

The basic structure of the diamond wire saw is divided into several ways according to the fixing method of the wire saw: plastic fixing (rubber fixing), spring fixing and plastic (or rubber) + spring combination fixing. The purpose of using injection molding plastic (or rubber, spring) to fix the wire saw is not only to fix the beads at equal intervals, to form a space for shavings and water, and to prevent the axial movement of the beads, another very important role is to prevent the beads from wrapping around the wire rope. turn.

Basic structure of plastic fixed (or rubber fixed) diamond wire saw

The diamond wire saw with plastic fixed (or rubber fixed) is mainly composed of four parts.

(1) Diamond beading: Beading is a cutting tool, and consists of a matrix and a steel matrix; the matrix contains a binder and diamond abrasive particles. The function of the matrix is to consolidate the diamond abrasive, and the broken rock is realized by the diamond particles. The nominal diameter of diamond beads is generally 7~12mm.

(2) Fixed sleeve: The fixed sleeve is used to isolate and fix the evenly distributed beads to prevent the beads from moving axially and rotating around their own axis. The fixing material must have various functions such as good elasticity, easy molding, high strength, corrosion resistance, wear resistance and aging resistance.

(3) Steel wire rope: The steel wire rope is used to connect diamond beads, which is equivalent to the “spine” of the entire beaded rope. It must have high fatigue strength, high breaking strength and low elongation.

(4) Joints: The beaded rope is closed at work, so the two ends of the beaded rope must be connected to a closed shape with a joint.

Basic structure of a spring-mounted diamond wire saw

The spring fixed diamond wire saw is mainly composed of six parts.

(1) Diamond beads.

(2) Washers (locating rings). Mainly used for spacing and isolation of beads, so that the position of the beads on the wire rope is accurate.

(3) Spring cover. It is used to separate the beads and make the beads move along the rope in a small range.

(4) Fixed ring. Generally, every five diamond beads on the beaded rope form a small cutting unit, that is, the five beads, springs and steel rings are limited within the range of about 17~18cm with a fixed ring. The function is that if the diamond beaded rope is broken during cutting, it can prevent the beads from shooting out of the wire rope like a bullet.

(5) Steel wire rope.

(6) Connector.

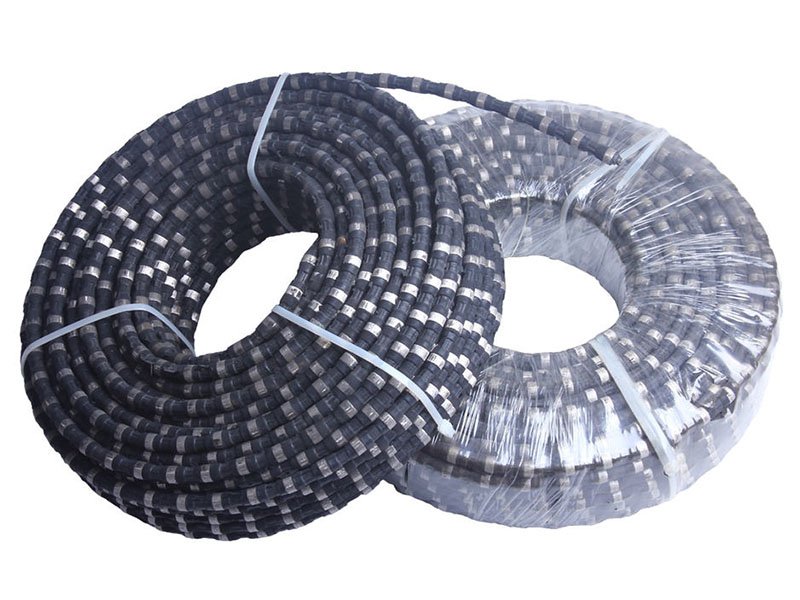

Inventory and Packaging

Sufficient inventory to ensure delivery and professional packaging to ensure safe transportation. Inner packaging: diamond wire saw are covered by plastic, then packed in carton; outer packaging is according to shipping method, if by air, we recommend carton which could reduce weight; if by sea, we recommend crate which is seaworthy. Other packaging is also available upon your request.

Manufacturing process of diamond wire saw for cutting concrete

The manufacturing process of diamond wire saw for cutting concrete mainly includes: cleaning of wire rope, preparation of diamond beads, forming or assembling of fixed sleeve and cutting edge, etc.

Cold Forming of Wire Saw Beads

The cold pressing of powder is to process the loose powder body into crushing with a certain size, shape, and certain density and strength. Cold pressing generally includes ordinary molding methods and special molding methods. The former is to put metal powder or other mixed powder in a specific die and press it into a press; the latter refers to non-compression molding, such as static pressure molding, continuous molding, pressureless molding, etc. Before cold pressing, it is usually necessary to prepare raw materials, such as annealing, mixing of various element powders, granulation and adding lubricants.

Cold-pressing molding process of metal powder: When a certain pressure is applied to the powder in the die, the powder particles will move relative to each other, and the powder particles will fill the pores to reduce the volume of the powder body. At the same time, after the powder particles are compressed, To withstand different degrees of elastic deformation and plastic deformation, there is a certain bond between the particles, so that the crush has a certain strength. In addition, due to the large internal stress accumulated in the compact during the pressing process, when the pressure is released, the compact will expand (elastic after-effect). Take out from the mold to complete the powder cold pressing process. Cold pressing means that after the loose powder is subjected to a certain pressing pressure in the die, the relative displacement between the powder particles occurs, the pores are filled, the powder volume is reduced, and the density is increased, becoming a powder with a certain size and shape and a certain density and strength. The process of compaction.

Cold pressing of beads for cutting concrete

There are two common methods for cold pressing of beads for cutting concrete:

One is to use split cold pressing, that is, after pressing the powder of the working layer into a cylindrical shape, the mold is unloaded. The steel matrix is put into the sintering mold together with the cold compact for sintering before sintering. The most prominent problem of this method is that during the sintering process, the air existing between the cold pressing and the steel matrix cannot be exhausted, and the bonding strength between the working layer matrix and the steel matrix after sintering is low.

The second is the use of integral cold pressing, that is, the powder of the working layer and the steel matrix are cold-pressed at one time. This method has the characteristics of convenient loading, assembly and mold removal, high yield of cold-pressed blanks and high production efficiency.

Cold forming process of diamond wire saw beads

Since the beads are thin-walled and long, and the hardness of the diamond is much greater than that of the mold, the ordinary cold press has a high pressing speed. If the pressing resistance is too high, it is easy to cause serious uneven density of the cold compact, cracks and breakage of the compact, and rapid wear of the cold pressing die. The cold pressing process of “fast forward – slow pressing – holding pressure – slow backward – fast backward” should be used to control the pressing speed.

Beading of diamond wire saws

The beads of the diamond wire saw must be fixed by the fixing material to achieve cutting. Due to the different fixing materials used, the fixing techniques are also different. The fixation of diamond wire saw beads means that after the beads are electrically connected by a wire rope of a certain length, the beads are arranged at regular intervals through certain fixing means (injection molding, glue injection, spring, etc.), and during the sawing process It plays the role of supporting and fixing the beads, storing water and containing chips, and making the beads form a tool with cutting ability. Another very important function of the use of injection-molded plastic (or rubber, elastic) in the wire saw is to prevent the beads from rotating around the wire rope.

In addition to the functions of connecting the beads through the wire rope into a whole, entraining the flushing liquid (cooling), and removing chips, the fixing material must also bear high-frequency impact loads, prevent the beads from moving axially and rotate around their own axes, corrosion-resistant, resistant to Wear, aging resistance and other functions; at the same time, the fixing material itself must also have the characteristics of good elasticity, easy molding and high strength. As a single use of spring fixation (mainly used for marble mining), the spring is required to have good stiffness and wear resistance, especially for the fatigue strength of the spring, which can withstand millions of times of compression and tension.

Contact Us

If you’re interested in Diamond Wire Saw for Cutting Concrete, please feel free to contact us, (E-mail: [email protected] Phone/WhatsApp: 0086-15805032000 or filling out the form below) we will keep providing quality products and excellent service for you.