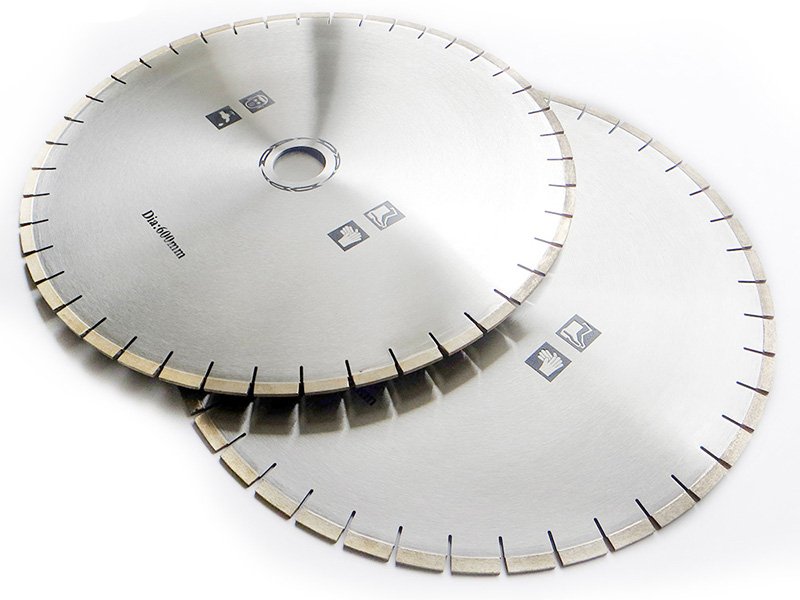

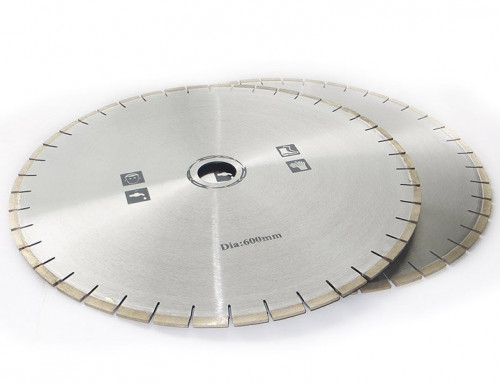

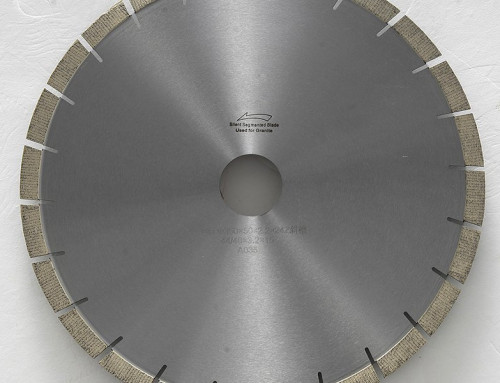

Best Diamond Circular Saw Blades Disc For Cutting Marble Tile Slab

1. Various diamond blade sizes and types available.

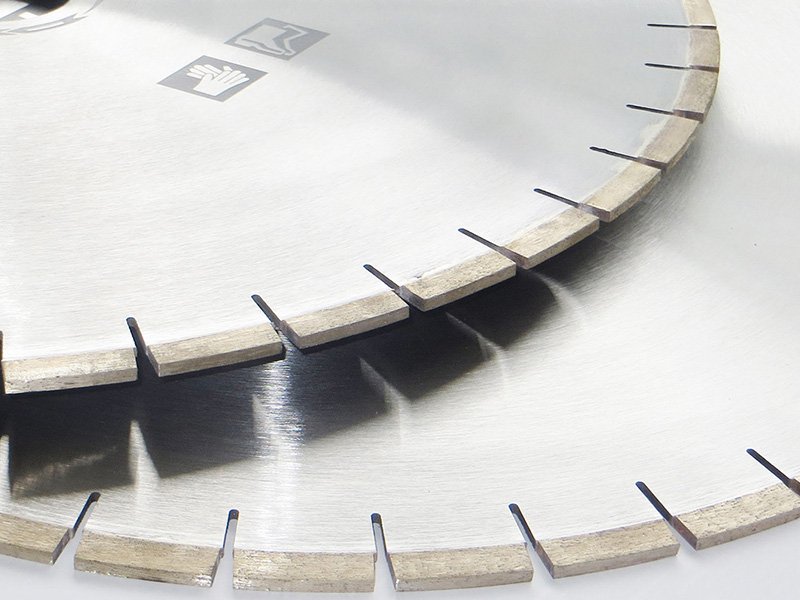

2. Excellent cutting result: stable cutting to ensure flat surface and even size.

3. Production capacity: our professional factory can supply 20,000 pieces/month.

4. Mature formula design and test system to guarantee high efficiency and long lifespan.

5. As a professional supplier, we can guarantee competitive wholesale price and stable quality.

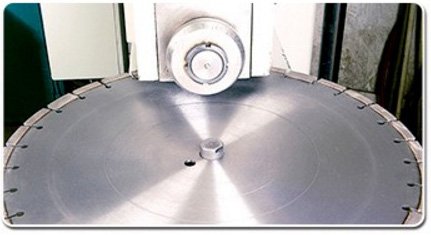

Sizes of Marble Diamond Saw Blades

The regular diameters of diamond saw blades range from 100mm to 3500mm. Among them, the popular sizes are: 2 inch, 3 inch, 3 3/8 inch, 4 inch, 4 3/8 inch, 4 1/2 inch, 5 inch, 5 3/8 inch, 5 1/2 inch, 6 inch, 6 1/2 inch, 7 inch, 7 1/4 inch, 7 1/2 inch, 8 inch, 8 1/4 inch, 9 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, 26 inch, 30 inch, 36 inch, etc. (110mm, 160mm, 165mm, 255mm, 300mm, 350mm, 400mm, 3m, etc.)

Saw Blades Processing Process

We have been focusing on the technical development and production of diamond tools for more than 28 years.

1. Powder Milling

2. Segment Pressing

3. Segment Sintering

4. Segment Welding

5. Welding Strength Inspection

6. Stress Release Rolling

7. Blade Polishing

8. Blade Painting

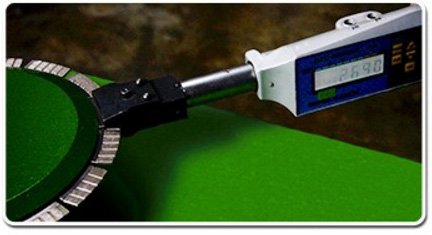

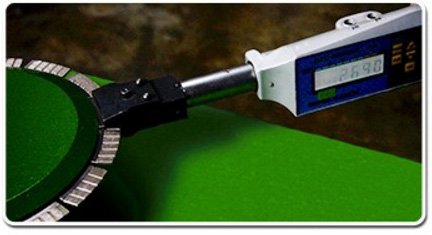

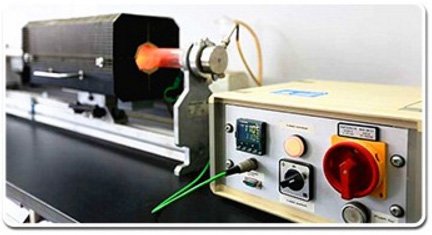

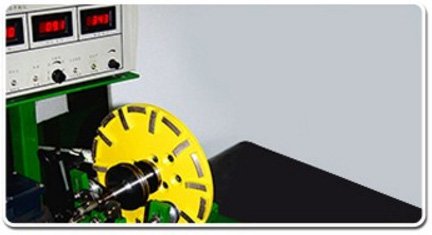

Quality Inspection

Excellent product quality is our commitment to customers as always.

Specifications of marble diamond circular saw blades

Diamond circular saw blades have a wide range of diameters, ranging from a few millimeters of engraving blades to several meters of large diameter circular saw blades. Different specifications of diamond circular saw blades have different application ranges.

Diamond circular saw blades with a diameter of 230mm and below

Most of these circular saw blades are manufactured by integral sintering process and laser welding process. It is mainly used for trimming, trimming and carving of stone, marble, granite, jade, crystal and other materials, as well as cutting and grooving of walls and reinforced concrete pavements. The circular saw blades manufactured by these two processes can realize waterless cutting.

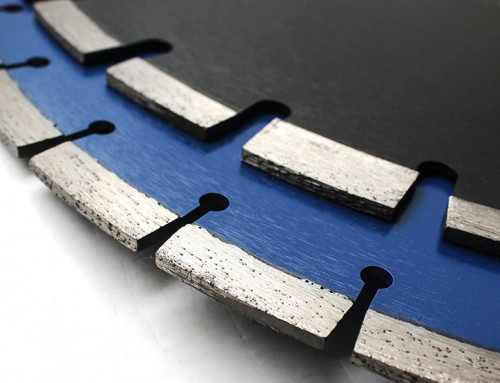

Diamond circular saw blade with a diameter of 230~400mm

This type of diamond saw blade can be manufactured by integral pressing and sintering process, laser welding process and high-frequency welding process. Material cutting. The circular saw blade manufactured by the overall sintering process and the laser welding process can be suitable for waterless cutting of high-speed stone cutting machinery.

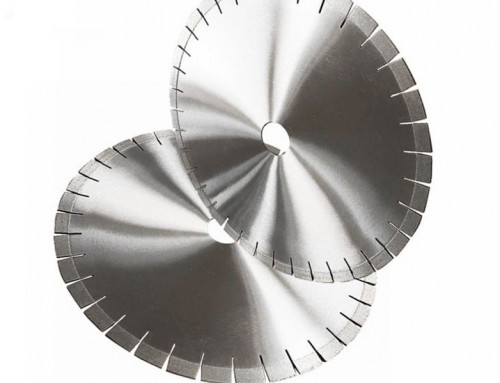

Diamond circular saw blades with a diameter of 600~1200mm

Most of these diamond saw blades are manufactured by high frequency welding or laser welding process.

Large saw blades with a diameter of 1200mm or more

Most of these diamond circular saw blades are welded by high frequency. Mainly used in the cutting of walls, prefabricated concrete, concrete, asphalt pavement and all kinds of stone blocks. The laser welding saw blade is suitable for larger depth cutting, and will not lose teeth due to insufficient water.

Classification of diamond saw blades

Diamond circular saw blades have a wide range of applications, such as cutting mines, cutting blocks, cutting marble, bridges and walls, etc. Among the common diamond circular saw blade products, according to the different cutting objects, diamond circular saw blades can be divided into the following categories: general-purpose diamond circular saw blades, stone cutting blades, concrete cutting blades, ceramic cutting blades, wall saw cutting blades, etc.

Universal diamond circular saw blade

The universal cutting blade is used for cutting engineering materials such as reinforced concrete, various types of stone, ceramic tiles, asphalt, etc. The cutting materials are rich in variety and have strong applicability.

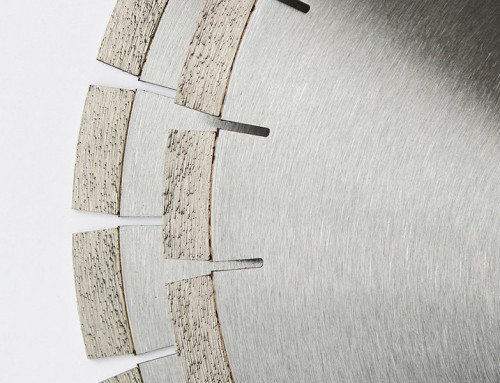

Diamond saw blade for cutting stone

This type of saw blade is mainly used in the cutting of granite, marble, sandstone and other stone materials. It is characterized by good sharpness, smooth cutting and good edge cutting effect.

Diamond saw blade for cutting concrete

The diamond saw blade for cutting concrete is mainly used for cutting concrete pavement, concrete pavement and components with reinforced steel, airport runway, highway, bridge, etc. It is characterized by high hardness of the cutter head, strong anti-abrasiveness, and the cutter head is mostly a block type, which can be cut by adding water.

Diamond saw blade for cutting asphalt

This type of saw blade is mainly used for cutting asphalt pavement and fresh concrete pavement, and the large size saw blade has a mouthguard or mouthguard block.

Saw blade for grooving

Saw blades for grooving are mainly used for the cutting of concrete, granite, cement, brick walls and other walls, sinks and seams on the ground. The saw blade is characterized by a large thickness of the cutter head, and the commonly used specifications are 105mm in diameter, 115mm in diameter, 150mm in diameter, 180mm in diameter, and 200mm in diameter. There are two common styles of saw blades for sharp angle grooving and flat tooth grooving.

Wall cutting saw blade

The wall-cutting saw blade is used to cut all kinds of reinforced concrete, stone and other building walls. The cutting seam is straight and the cutting is stable. It is suitable for special wall-cutting machinery.

Saw blades for tiles

Professionally used for the cutting of ceramic tiles, it can cut various types of ceramic tiles such as glazed tiles, high-hardness antique tiles, and vitrified tiles. It is characterized by fast cutting speed and stable cutting, which can ensure that the cut tiles are less chipped. There are two types of common tile cutting saw blades: one is sintered, and the other is welded. In the cutting of tiles, multi-piece combined cutting is often used, which can improve the cutting efficiency and cut mosaics.

Diamond inner circle cutting disc

The characteristics of diamond inner circle cutting blade are that the blade can be made very thin, the slit is narrow, the processing precision is high, and the efficiency is high, which can reduce the loss of precious materials.

Diamond ultra-thin cutting disc

High-precision diamond ultra-thin cutting discs are mainly used for cutting and grooving various electronic components in the field of electronic information and precision parts in the machinery industry.

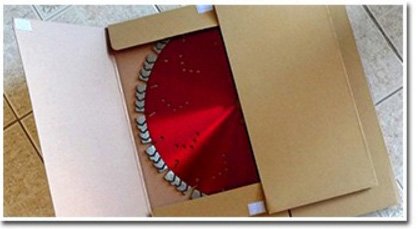

Inventory and Packaging

Sufficient inventory to ensure delivery and professional packaging to ensure safe transportation. Inner packaging: diamond saw blades are covered by anti-rust paint and plastic, then packed in paper box. Outer packaging is according to the shipping method, if by air, we recommend carton which could reduce weight; if by sea, we recommend crate which is seaworthy. Other packaging is also available upon your request.

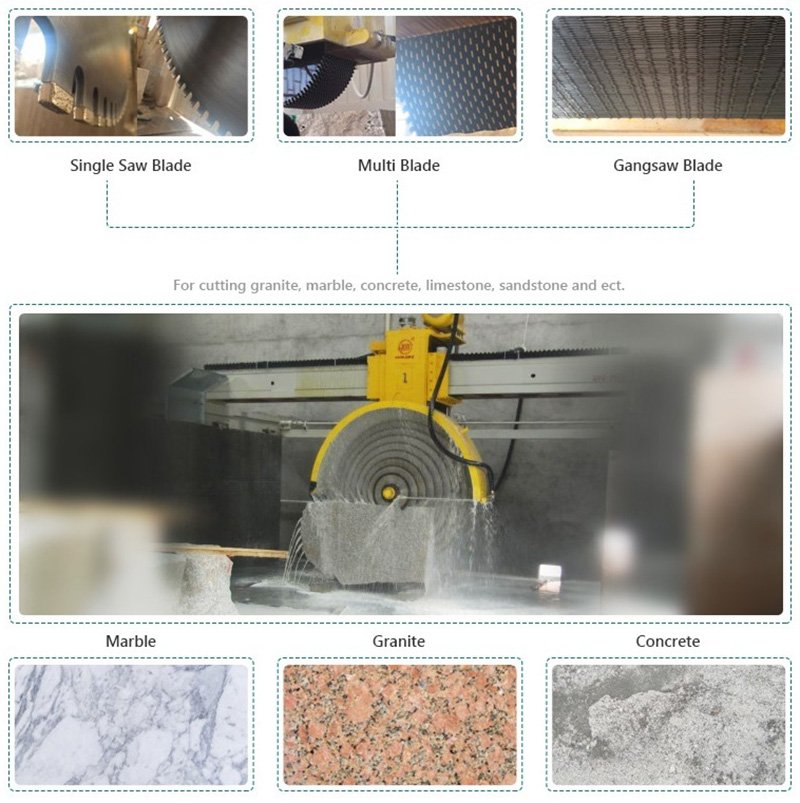

Application of Diamond Cutting Blades

For multi blade cutter, gang saw blade, bridge cutting machine, single arm cutting machine, manual handing machine, able cutting machine, etc. Designed for various hardness stone (soft, medium hard and very hard stones) cutting: granite, marble, sandstone, onyx, limestone, travertine, quartz stone, artificial stone, andesite, volcanic, lava stone, basalt, microcrystal stone, blue stone, dolomite and construction materials (concrete, tile, ceramic, asphalt, floor) to reduce segment cost and increase cutting efficiency.

How to use diamond saw blades for cutting marble

When selecting a diamond saw blade, carefully read the instructions for use of the saw blade. For saw blades of different specifications and uses, the design of the cutter head formula and the matrix form are different, and should be selected according to their corresponding occasions. The specification and safe use of diamond saw blades are issues that cannot be ignored in the use of diamond saw blades. Only by using the diamond saw blade in a standardized and safe manner can the operator’s personal safety be effectively protected, the cutting performance of the saw blade can be better improved, and the user can operate more comfortably. The following are the aspects that should be paid attention to when using marble diamond circular saw blades,

(1) The transportation and storage of the saw blade should pay attention to preventing deformation to ensure accuracy. If you do not use it immediately, you should lay it flat or use the inner hole to hang it. Do not stack other items or feet on the flat saw blade, and pay attention to moisture and rust prevention.

(2) When installing the saw blade, keep the shaft, chuck and flange clean to prevent rust and ensure that the flange and the saw blade are tightly combined. The size and shape and position accuracy of the main shaft and the splint of the equipment have a great influence on the use effect, and should be checked and adjusted before installing the saw blade. In particular, the factors that affect the clamping force and cause displacement and slippage on the contact surface of the splint and the saw blade must be excluded. The size of the flange should be appropriate, about 1/3 of the diameter of the saw blade.

(3) When assembling, the power supply must be cut off, and the matching error between the motor shaft and the central hole of the saw blade must be less than 01mm. Be careful to keep the direction of the arrow marked on the saw blade consistent with the direction of rotation of the tool being used.

(4) Please do not apply side pressure or curve cutting when cutting, and the feed should be stable. Avoid impact contact of the blade with the workpiece to avoid danger.

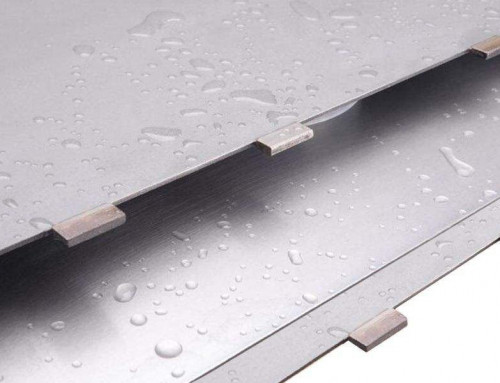

(5) When dry cutting, please do not cut continuously for a long time, so as not to affect the service life and cutting effect of the saw blade; for wet cutting, water cutting should be added to prevent leakage.

(6) The wet cutting machine should be cooled with water to prevent leakage.

(7) The operator should use protective cover, protective mask, work clothes, protective shoes, gloves and other labor protection supplies.

(8) After the saw blade is installed, idle for a few minutes, and then work normally without slipping, swinging or jumping. The blunt saw blade can be cut on the grinding wheel or refractory brick, and the sharpness is better.

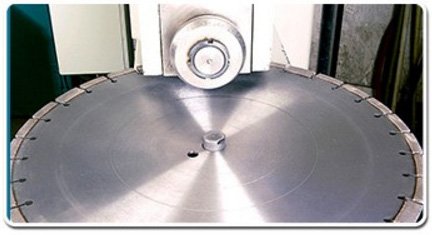

Stone Cutting Machinery

All parts of the stone cutting machine should have sufficient precision, run smoothly, and have low noise. The rotating spindle, saw blade movement or table movement should meet the design requirements. Before the saw blade is installed, the running accuracy of the cutting machine should be checked. In general, the straightness and parallelism of the stone cutting machine are within 004mm, the axis of the saw blade shaft should be perpendicular to the moving direction (track) of the table, and the perpendicularity should be within 0.04mm. If it does not meet the requirements, it should be debugged or repaired immediately. The lubricating oil and engine oil must be replaced after the stone cutting machine runs for 4 to 6 months. The lead screw, guide bar, guide rail sliding and rotating parts should be checked regularly and lubricated, and the beam guide rail should be checked before starting the machine, and there must be no items on it. After each shift, the above parts should be lubricated with oil. Regularly check each screw connection and V-belt, and regularly remove stone powder. The power of the main motor of the stone cutting machine should match the diameter of the saw blade and the material of the stone to be cut.

Coolant

The cooling of the diamond circular saw blade is generally water cooling, which prevents the stoning of the diamond at high temperature and the softening of the metal binder, and also plays the role of chip removal, washing away the stone chips generated during the cutting process, preventing the stone chips. Secondary wear occurs. The flow of cooling water should be sufficient.

Installation of circular saw blades

When installing the saw blade, first clean the rust and oil on the shaft and flange. Check the direction of the arrow on the base of the saw blade. The cutting rotation direction of the saw blade should be consistent with the direction of the arrow. Do not change the cutting direction during the cutting process, otherwise the diamonds on the saw teeth will easily fall off and reduce the service life of the saw blade. The main function of the flange is to locate, reinforce and transmit torque, to ensure the correct installation position of the saw blade, and to reduce the yaw and vibration of the saw blade during cutting. The inner hole of the flange should be coaxially matched, and the third level of precision can be selected. The diameter of the flange should be adapted to the diameter of the saw blade, which is generally about 1/3 of the diameter of the saw blade. In the case of ensuring the cutting size down, the bigger the better.

Influence of sawing parameters

The sawing parameters are an important factor affecting the cutting. The sawing parameters include: the linear speed of the saw blade, the feed speed and the feed amount of the saw blade. The feed speed of the saw blade is determined by the properties of the material being sawed, and there is a certain range of feed speed for each material when the depth of cut is certain. If the feed speed is too fast, the diamond will wear and fall off faster; if the feed speed is too low, the wear of the matrix will be slowed down, resulting in the phenomenon of “blunt and slippery”. With the increase of the feed speed, the service life of the saw blade decreases, and the larger the feed amount, the more obvious the decreasing trend of the service life. The amount of feed, that is, the depth of single sawing, is an important parameter involving diamond wear, effective sawing, the force of the saw blade and the properties of the material being sawed. According to the different properties of the cutting material, the cutting depth is different. When the material is soft or medium hardness, a larger cutting depth can be used. When the material hardness is high and the abrasiveness is strong, the cutting depth is smaller. When the linear speed of the saw blade is large, a large cutting depth can be selected, but when there is a requirement for the machined surface, a small depth cutting should be used. Generally, the cutting depth of diamond saw blades can be selected between 1~60mm.

We define the product of the feed speed of the saw blade and the feed amount as the cutting efficiency, which represents the area cut per unit time, that is, the processing efficiency of the saw blade. The life of the saw blade decreases with the increase of cutting efficiency; the power consumption increases with the increase of cutting efficiency, and the lower the feed speed, the more significant. The linear speed of the saw blade should be adapted to the hardness and wear resistance of the sawing object. During cutting, the life of the saw blade and the cutting efficiency have the best speed. When the cutting efficiency is improved, the favorable speed of the saw blade moves to the high-speed side. , the power consumption increases with the speed of the saw blade, and the high cutting efficiency is especially obvious.

Therefore, when cutting different objects, the saw blade has an optimal range value. For example, when cutting granite, the linear speed of the saw blade can be selected within the range of 25~40m/s. For granite with high quartz content that is difficult to saw, the lower limit of the linear speed of the saw blade is appropriate. The linear speed can reach 40m/s when cutting softer granite.

Contact Us

If you’re interested in Best Diamond Circular Saw Blades Disc For Cutting Marble, please feel free to contact us, (E-mail: [email protected] Phone/WhatsApp: 0086-15805032000 or filling out the form below) we will keep providing quality products and excellent service for you.